One Bag for All Scenarios-Multiple Commercial Applications of T-shirt Plastic Bags

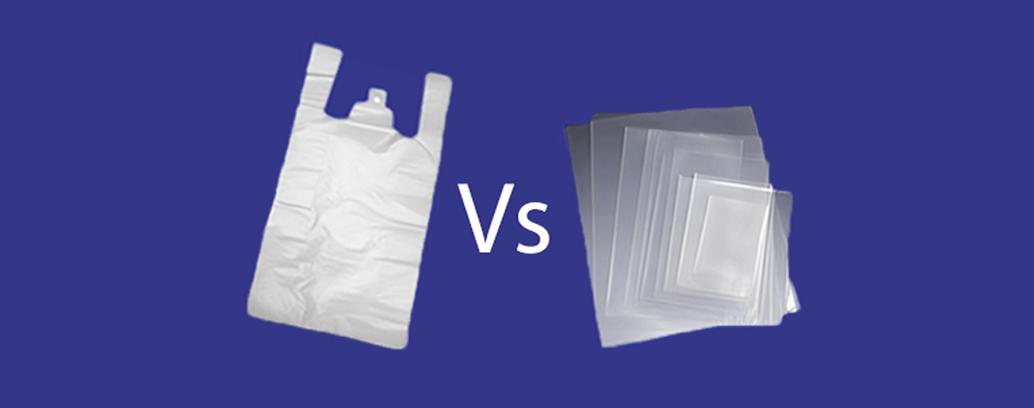

T-shirt plastic bags are a major category of plastic bags and an indispensable part of daily life.

Our plastic T-shirt bags offer comprehensive customization services—we provide 100% customization for materials (LDPE/HDPE), usage scenarios, logos, packaging styles, and graphics, tailored to your specific needs.

1. Material Options-Tailored to Your Requirements

HDPE (High-Density Polyethylene) and LDPE (Low-Density Polyethylene) are the two core subcategories of PE (Polyethylene) and the mainstream raw materials for plastic bag production. Their fundamental differences lie in chemical molecular structures.

HDPE-Features molecular chains with few branches (low proportion of short branches), regular arrangement, and high crystallinity (70%-80%), resulting in strong intermolecular forces. With a density range of 0.941-0.965g/cm³ and a melting point of 126-136℃, its high crystallinity ensures a dense texture. It is commonly known in the industry as "rigid PE" or "low-pressure polyethylene."

LDPE- Has molecular chains with numerous branches (high proportion of long branches), loose arrangement, and low crystallinity (40%-50%), leading to weak intermolecular forces. With a density range of 0.910-0.940g/cm³ and a melting point of 105-115℃, its low crystallinity delivers a flexible texture. It is commonly referred to as "flexible PE" or "high-pressure polyethylene."

2. Material Properties & Advantages

| Material | Key Physical Advantage | Performance Highlights |

| HDPE | High tensile strength, tear resistance, puncture resistance, excellent load-bearing capacity (5-20kg) | Rigid, thick hand feel, strong stability, non-deformable; suitable for high-load, breakage-proof scenarios |

| LDPE | Superior flexibility, impact resistance, foldable, non-breakable | Soft, lightweight hand feel, good fit; ideal for wrapping, rubbing-resistant applications |

3. Core Performance Comparison

HDPE- Medium transparency and gloss; high temperature resistance; resistant to acids, alkalis, oils, and organic solvents (e.g., alcohol, detergents); recyclable (recycling number "2"); slightly higher processing costs and stricter process requirements.

LDPE- High transparency and gloss (clearly displays internal items); low temperature resistance; moderate resistance to acids, alkalis, and oils (weaker organic solvent resistance than HDPE); recyclable (recycling number "4"); lower raw material costs, simple processing, high mass production efficiency, and competitive unit prices.

Note- Even our LDPE T-shirt bags are thickened—unlike conventional thin disposable PE bags, they are more durable and robust.

4. Processing Technology

Both HDPE and LDPE follow the core process of "plasticization - film formation - bag making," but their molecular structure differences require distinct temperature, pressure, equipment parameters, and processes.

HDPE- Due to high crystallinity (70%-80%), regular molecular chains, and high viscosity, the key processing principles are "high-temperature plasticization, low blow-up ratio, and rapid cooling" to ensure density and strength. It is mainly produced as thick films, can be added with fillers to enhance hardness, supports complex logo printing (surface corona treatment required), and is suitable for flat bags, T-shirt bags, and stand-up pouches.

LDPE- With low crystallinity (40%-50%), branched molecular chains, and low viscosity, the processing focus is "medium-temperature plasticization, high blow-up ratio, and gentle cooling" to maintain flexibility, transparency, and fit. It is primarily produced as thin films, easy to mold into special-shaped bags and ziplock bags, and delivers excellent gloss after printing.

Summary- Choose HDPE for "high load-bearing and durability"; opt for LDPE for "thinness and high transparency."

5. Wide-Ranging Application Scenarios

• Food Industry

-HDPE T-shirt plastic bags are manufactured with a focus on durability and high load-bearing capacity.They are suitable for food delivery, dry goods in supermarkets (e.g., rice, nuts), heavy-load packaging in farmers' markets (e.g., meat, fruits, vegetables), and frozen food transportation.

- LDPE T-shirt bags focus on preservation and display-ideal for temporary packaging of chilled meat and fresh produce to lock in moisture and enhance freshness.LDPE T-shirt bags used for portioning snacks, bread, and fresh produce in supermarkets showcase contents clearly without damaging surfaces—soft, non-toxic, and food-grade compliant.

• Industrial Sector

-HDPE's high-strength properties are fully demonstrated here. For example, industrial-grade load-bearing T-shirt bags (for small/medium mechanical parts, electronic components) offer excellent wear resistance, preventing puncture from sharp edges. HDPE chemical-resistant T-shirt bags are also suitable for temporary transfer of chemical auxiliaries, providing reliable chemical resistance and leak-proof performance.

-LDPE, on the other hand, emphasizes protective functions.Its soft texture makes it ideal for packaging electronic products (e.g., mobile phones, headphones) to prevent scratches. Industrial-grade LDPE T-shirt bags are perfect for temporary packaging of workshop cleaning supplies and small tools—easy to fold, dust-proof, and well-sealed.

• Retail Food Sector

-Common applications include supermarket shopping bags, pet product T-shirt bags, cleaning/storage T-shirt bags, and garbage bags. HDPE's stable structure and tear resistance allow for logo printing and heavy-load carrying, fully meeting daily usage needs.

-LDPE packaging is typically used for promotional trial bags and sample bags of daily care products, offering high transparency and preventing leakage caused by extrusion.

• Agricultural Field

-HDPE bags in this sector prioritize weather resistance. UV-resistant agricultural T-shirt bags can hold outdoor fruits, vegetables, and field work tools. Agricultural portable T-shirt bags are suitable for portioning crop seeds, chemical fertilizers, organic fertilizers, horticultural nutrient soil, and feed—HDPE’s moisture resistance ensures product preservation.

-LDPE perforated breathable T-shirt bags are ideal for transporting fresh produce, as their soft, form-fitting design avoids surface damage. Cost-effective and disposable, they are also suitable for packaging flower seedlings and small agricultural tools.

• Medical Industry

-HDPE is primarily used for its breakage resistance, chemical resistance, and compatibility with high-temperature sterilization—common applications include medical waste bags and T-shirt bags for medical equipment accessories.

-LDPE sterile T-shirt bags for medical consumables and storage bags for medical supplies, by contrast, prioritize safety, non-toxicity, easy sterilization, breathability, and softness.

From material selection, performance advantages, and processing technology to application scenarios, this overview provides a comprehensive understanding of our T-shirt plastic bags. Customize your exclusive plastic bag products based on your business sector and target customers!

English

English Español

Español